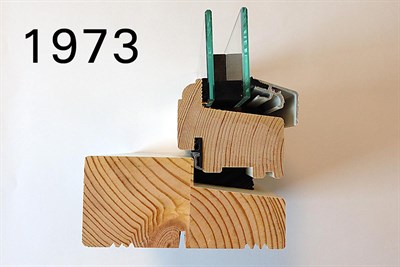

The figures below illustrate the general development trends

for window sash and frame in Scandinavia within the last 40 years

with examples from Winsmart project partner IDC. Up until the

1970's window frames were largely produced in wood, primarily

heartwood from Scots pine. The purpose of the sash/frame was to

hold the glazing in place and allow the window to be opened.

Insulation properties was not a major driving force for development

at this stage.

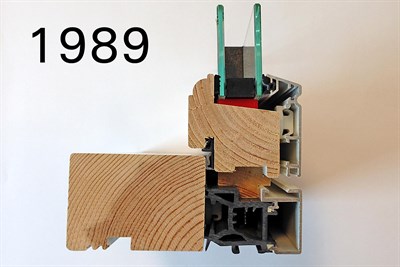

In the 1980's, maintenance and service life became important

development drivers. In windows, wood is viewed as a high

maintenance material. Wood is susceptible to biodegradation by

decay fungi (rot) and to dimensional instability due to its

hygroscopic properties. Wood windows therefore require a relatively

high level of maintenance - in the form of surface treatment

(painting) at regular intervals - to be kept sound. Consequently,

window producers gradually began to limit the amount of wood in the

parts of the window exposed to the weather. The figure below shows

a window with an aluminum profile attached on the outside of both

sash and frame to protect the wood from direct exposure to the

elements. The aluminum profile increases the durability of the

window and lowers the maintenance requirements for the consumer.

However, the main part of both sash and frame is still wood which

was typical for the Scandinavian window market at the time.

Elsewhere in Europe, especially in in Germany, the development

trend went towards eliminating the use of wood in windows

altogether, and to produce window sash/frame exclusively in PVC or,

later on, aluminum.

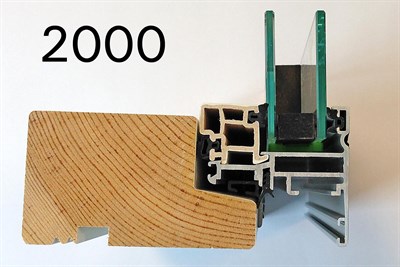

Mainly driven by architects, sash and frame design became an

important development factor from the 1990's onwards. The sash and

frame part of the window should be as slim as possible to increase

the amount of light per window opening and to make the window look

more elegant from the outside. This is evident in the figure below,

which shows a considerably slimmer design compared to the figures

above. The sash is now designed to be an extension of the frame

rather than closing in on top of the frame. The trend of limiting

the use of wood is continued and the sash is now constructed of

pure aluminum with no use of wood. Still, insulation properties and

energy efficiency were not the main development drivers.

From the turn of the millennium to the present day, energy

efficiency has grown increasingly important as a development factor

for window sash/frame design and is now perhaps the main driver for

sash and frame development. The development has been partly market

driven because the ever-increasing energy costs coupled with

increased environmental consumer awareness has resulted in an

increased demand for energy efficient windows. In addition,

legislative action has put minimum demands on the energy efficiency

of windows in newly constructed buildings.

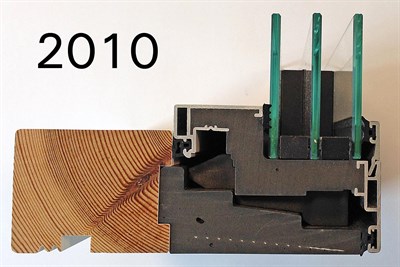

The figure below shows a profile of FUTURA+, a state-of-the

art Scandinavian window from IDC. The entire sash and the outer

part of the frame is made of rigid poly-urethane foam (PUR) with a

density high enough to give it the structural properties needed to

support the weight of the triple glazing and to give the whole

window structural stability. At the same time, PUR provides good

insulation properties due to the relatively low thermal

conductivity (λ-value) of PUR foam compared to wood, PVC, and

aluminum. Two versions of FUTURA+ is produced: one for the

Scandinavian market opening out and another for the central

European market opening in. The Scandinavian version (below) is

designed with wood on the interior part facing the consumer while

the central European version has aluminum facing the customer.

The U-values of the FUTURA+ window as a whole (Uw) is

0.87 for the Scandinavian version opening out and 0.83 for the

central European version opening in with triple glazing

installed.

Sash and frame in Winsmart

As described above, current state of the art windows have a

Uw-value in the range of 0.8. With this background, the

winsmart objective of reaching a Uw-value of 0.3 is very

ambitious, especially when you consider the additional objectives

of lower weight, reduced embodied energy, and lower production cost

compared to state-of-the-art.

The window sash and frame design should enable the overall

winsmart objectives as well as provide structural support for the

VIG and the switchable technology. These goals will be achieved

through use of the latest technology materials with extremely low

thermal conductivity.

This project has received funding from the European

Union Seventh Framework Programme (FP7/2007-2013) under grant

agreement n° 314407.