The potential and current limitations of Vacuum

Insulation Glazing (VIG)

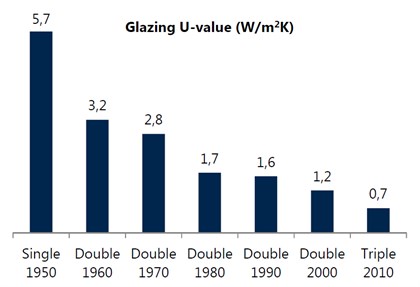

The insulation performance of windows has dramatically increased

during the last fifty years. The U-value of a state-of-the-art

triple glazing unit is around 0.7 W/(m2·K), which is

still higher than that of a well-insulated wall, with U-values as

low as 0.15 W/(m2·K).

Historical evolution of glazing performance. For comparison,

a well-insulated wall has a U-value of 0.15

W/(m2·K).

Vacuum Insulation Glazing (VIG) have potential U-values lower

than 0.3 W/(m2·K), but currently available products do

not even approach these values due to technical limitations. One of

the most critical aspects of VIG is the edge seal. For typical

products, the edge between both panes is sealed by a

PbO-SiO2 based solder glass before evacuation and

sealing of a pump-out hole. The result is a rigid edge seal and a

visible pump-out hole in one of the corners of the glazing. The

rigidity of the edge seal imposes limitations on the performance of

the VIG unit: for large sizes of highly insulating glazing, large

temperature differences between the inner and outer pane result in

differential expansion of the panes, which may bend and break the

VIG.

The Winsmart VIG

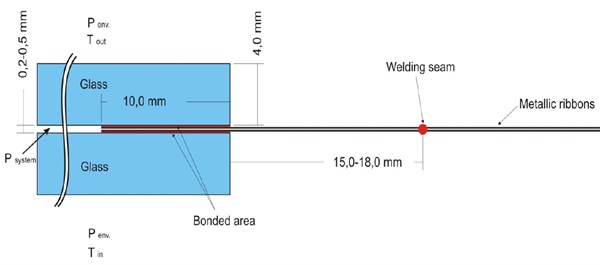

The Winsmart strategy overcomes these problems by using a

flexible edge seal that consists of laser-welded metallic ribbons.

In a first step, metallic ribbons are soldered onto both glass

panes under atmospheric pressure. In the second step, the VIG is

created by laser-welding the metallic ribbons inside a vacuum

chamber. The result is a VIG unit with a flexible edge seal and

without a pump-out hole.

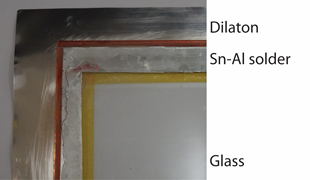

Schematic cross-section of the Winsmart edge-sealing

technology.

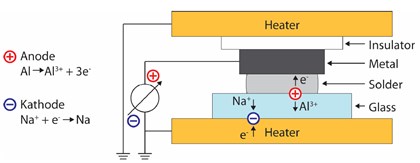

Glass-to-metal bonding by liquid solder anodic

bonding

The bonding of metal to glass is notoriously difficult and often

requires metallization of the glass surface before bonding. The

ALTSAB process combines anodic bonding with the use of an

activated liquid tin solder to produce strong hermetic seals. The

liquid solder can accommodate surface roughness and negates the

need for surface pre-treatment or the application of high

mechanical force during the bonding process.

Schematic illustration of the ALTSAB process (Figure from

Elrefaey et al. 2014). The application of a high electric field

(500-1000 V) oxidizes the activating element in the solder (Al)

near the glass-solder interface, dramatically improving bond

strength and the wetting of the glass with liquid thin. At the same

time, the metal-solder bond is forms by soft soldering.

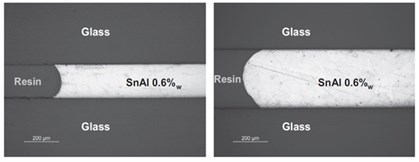

The application of a high voltage (left) dramatically

improves the wetting of the glass by the solder (Figure from

Koebel et al. 2011).

Early glass-to-metal bonding prototype.

Laser welding of metallic ribbons under

vacuum

After bonding the metallic ribbons, a pair of glass panes is

transferred to a vacuum chamber (P < 1E-5 mbar). The spacers

have to be placed before in a way that they don't influence the

optical characteristic of a window. In the vacuum tunnel a plasma

cleaning process is applied to avoid excessive degassing of the

final VIG unit. Then, the top pane is lowered onto the spacers

positioned on the bottom pane and the metallic ribbons are clamped

together. Finally, the metallic ribbons are laser-welded to form a

hermetic seal, while the laser itself is outside of the vacuum

chamber.

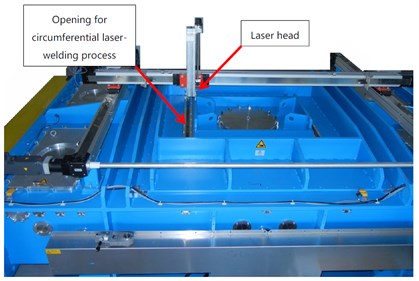

Vacuum chamber with laser-welding equipment for 1m x 1m

glass panes.

The advantage of this method is the hermetic sealing without

pumping the VIG afterwards. The joint glass panes leave the vacuum

chamber as a complete VIG.

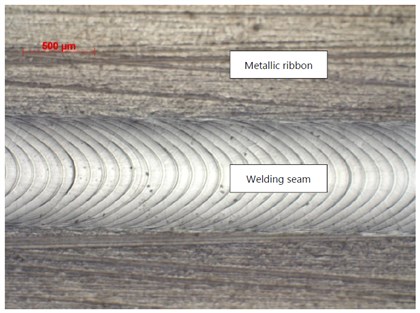

Close-up (top-view) of the laser-welded edge seal. The high

degree of overlap ensures a hermetic seal.

This project has received funding from the European

Union Seventh Framework Programme (FP7/2007-2013) under grant

agreement n° 314407.